Understanding Punch Press Machines: An In-Depth Guide

Release Time : 2024-07-16 View Count : 次Punch press machines are pivotal in the manufacturing industry, enabling precise and efficient metal forming and cutting operations. This article delves into the intricacies of punch press machines, exploring their components, working principles, types, applications, advantages, and maintenance.

What is a Punch Press Machine?

What is a Punch Press Machine?

MC

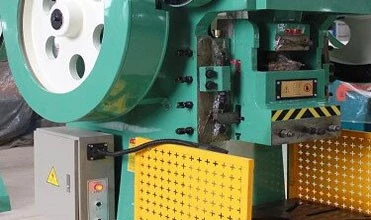

A punch press machine is a type of machine press used to cut holes in materials. It works by using a punch and die system, where the punch is driven into the material by mechanical or hydraulic force to create holes or shapes. These machines are integral to operations in automotive, aerospace, construction, and various other industries due to their versatility and precision.

Components of a Punch Press Machine

Components of a Punch Press Machine

MC

The primary components of a punch press machine include the frame, bed, ram, punch, die, and drive mechanism. The frame provides structural support and houses other components. The bed is a flat surface where the material is placed. The ram, driven by the drive mechanism, moves up and down, pressing the punch into the material. The punch and die work together to form holes or shapes, with the punch pushing the material into the die to create the desired cut. The drive mechanism can be mechanical, hydraulic, or pneumatic, determining the force and speed of the punching process.

Working Principles of a Punch Press Machine

Working Principles of a Punch Press Machine

MC

The working principle of a punch press machine involves a series of coordinated movements. The material is positioned on the bed, aligned with the die. When the machine is activated, the ram descends, driving the punch into the material. The punch forces the material into the die, cutting it into the desired shape. After the punching operation, the ram retracts, allowing the material to be removed or repositioned for the next punch. This cycle can be repeated rapidly for mass production.

Types of Punch Press Machines

Types of Punch Press Machines

MC

Punch press machines can be categorized into different types based on their drive mechanism and operation. Mechanical punch presses use a flywheel and crankshaft to generate punching force, offering high speed and precision. Hydraulic punch presses use hydraulic cylinders to drive the ram, providing adjustable force and smooth operation, ideal for thicker materials. Pneumatic punch presses use compressed air to generate force, suitable for lighter materials and smaller operations. Additionally, CNC punch presses incorporate computer numerical control for automated and highly precise punching, enhancing efficiency and consistency in production.

Applications of Punch Press Machines

Applications of Punch Press Machines

MC

Punch press machines have a wide range of applications across various industries. In the automotive industry, they are used to create components like brackets, frames, and panels. In aerospace, they help manufacture intricate parts for aircraft. The construction industry utilizes punch presses for fabricating structural components, while the electronics industry employs them for producing precise enclosures and brackets. Punch presses are also used in the production of household appliances, furniture, and agricultural equipment, demonstrating their versatility and indispensability in modern manufacturing.

Advantages of Punch Press Machines

Advantages of Punch Press Machines

MC

The advantages of punch press machines are numerous, making them a preferred choice in manufacturing. They offer high precision, ensuring consistent quality and accuracy in every punch. Their speed and efficiency enable mass production, reducing manufacturing time and costs. Punch presses are versatile, capable of handling various materials and thicknesses. The ability to automate punching operations with CNC technology further enhances productivity and reduces human error. Additionally, punch press machines are relatively easy to maintain and operate, contributing to their widespread adoption in the industry.

Maintenance and Troubleshooting of Punch Press Machines

Maintenance and Troubleshooting of Punch Press Machines

MC

Proper maintenance is crucial for the optimal performance and longevity of punch press machines. Regular inspection and lubrication of moving parts, such as the ram and drive mechanism, prevent wear and tear. Ensuring that the punch and die are correctly aligned and free of damage maintains cutting precision. Periodically checking and tightening bolts and fasteners enhances machine stability. Troubleshooting common issues, such as misalignment, inadequate punching force, or unusual noises, involves examining the drive system, hydraulic fluid levels (for hydraulic presses), and ensuring proper material positioning. Routine maintenance and timely troubleshooting minimize downtime and extend the lifespan of the machine.

Contact Us to Order

Contact Us to Order

MC

Are you looking to enhance your manufacturing capabilities with a state-of-the-art punch press machine? Look no further! Our company offers a wide range of punch press machines tailored to meet your specific needs. Whether you require a mechanical, hydraulic, pneumatic, or CNC punch press, we have the perfect solution for you.

Our team of experts is ready to assist you in selecting the right machine and providing comprehensive support throughout the purchasing process. Contact us today to discuss your requirements, request a quote, or schedule a consultation. You can reach us via phone, email, or by filling out the contact form on our website. Enhance your production efficiency and precision with our high-quality punch press machines.

Contact:Mr. Liu

Phone:13322202758

QQ:605712576

Email:liu@mingchenggroup.com

website:www.weldingcut.com

Address:20 Gangwan Street, Zhongshan District, Dalian City, Liaoning Province, China