Welcoming Azerbaijani Customers: A Comprehensive Guide to Showcasing Our Dished End Machines

Release Time : 2024-07-09 View Count : 次As the global market becomes increasingly interconnected, welcoming international customers to your factory can significantly enhance business relationships and showcase your capabilities. We are eagerly anticipating the visit of our Azerbaijani customers, who will be traveling from far across the ocean to explore our state-of-the-art dished end equipment. This visit presents an excellent opportunity to demonstrate our expertise, build trust, and potentially secure long-term partnerships.

MC

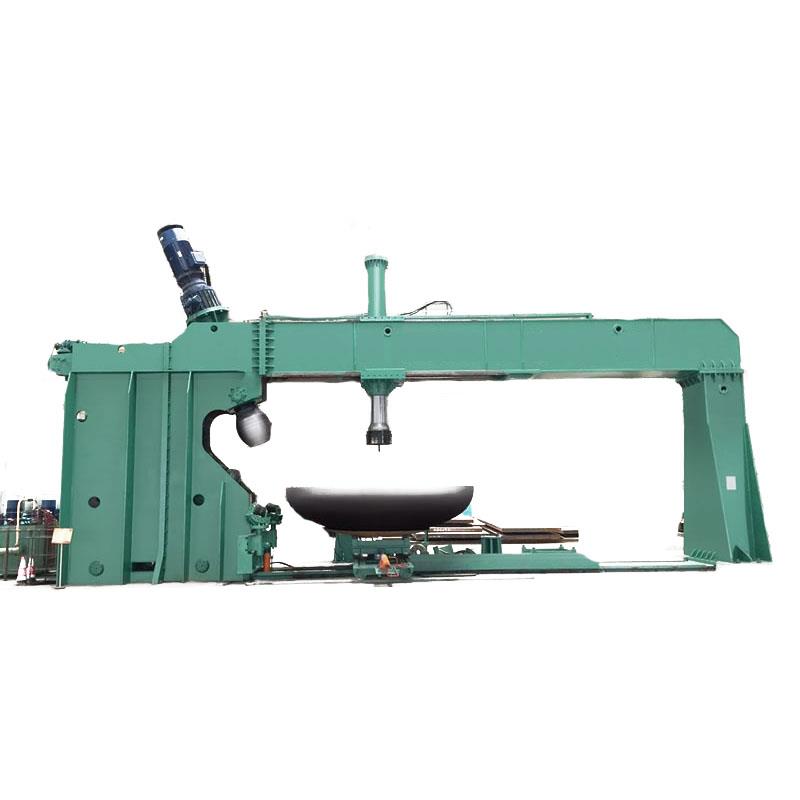

What Is A Dished End Machines?

A dished end machine is a specialized piece of industrial equipment used in the manufacturing of dished ends, which are essential components of pressure vessels, storage tanks, boilers, and other cylindrical equipment. These ends, also known as heads or caps, are typically hemispherical, torispherical, or ellipsoidal in shape, and they serve to close the ends of cylindrical vessels, thereby containing the contents under pressure or vacuum.

MC

Working Principles of Dished End Machines

The working principle of a dished end machine revolves around precision forming techniques using hydraulic or mechanical presses and spinning mechanisms. Metal blanks are placed between upper and lower dies, where high pressure from the presses molds the material into the desired hemispherical, torispherical, or ellipsoidal shapes. Alternatively, some machines employ rotary tables and forming rollers to spin the metal blank, ensuring uniform thickness and curvature. Edge trimming and beading techniques follow to refine the edges, ensuring a precise fit and enhancing the structural integrity of the dished ends used in pressure vessels, storage tanks, and boilers.

MC

Advantages of Dished End Machines

Dished end machines offer numerous advantages, starting with precision and consistency. These machines provide high precision in forming, ensuring consistent quality across multiple units. This level of accuracy is crucial for maintaining the integrity and safety of pressure vessels and other cylindrical equipment. Versatility is another significant advantage. Dished end machines can handle various metals, including steel, stainless steel, aluminum, and more, making them suitable for different industrial applications. This adaptability allows manufacturers to meet diverse customer requirements effectively.

Efficiency is a hallmark of dished end machines. Automated processes and high-capacity presses enable rapid production, significantly reducing manufacturing time and costs. This efficiency translates to higher productivity and cost savings for manufacturers. Additionally, these machines offer customization options. They can be adjusted to produce dished ends of different sizes and shapes, catering to specific customer needs. This flexibility ensures that manufacturers can deliver tailored solutions that meet precise specifications.

MC

Applications of Dished End Machines

The applications of dished end machines are vast and varied, spanning multiple industries. One of the primary applications is in the manufacturing of pressure vessels. These vessels are used in industries such as oil and gas, chemical processing, and power generation, where they must withstand high pressures. Dished ends are critical components in these vessels, providing the necessary strength and durability to contain pressurized contents safely.

Storage tanks also rely on dished end machines for their construction. These tanks are employed in the storage of liquids and gases, including water, chemicals, and fuels. The precision and reliability of dished ends are essential for maintaining the integrity of these tanks. Boilers are another significant application. Dished end machines are used in the manufacturing of boilers for steam generation in various industries, including power plants and manufacturing facilities. The high-quality dished ends produced by these machines contribute to the efficiency and safety of boiler systems.

Heat exchangers benefit from the use of dished end machines as well. These machines are utilized in creating components for heat exchangers, which are critical in thermal management systems. Dished ends play a crucial role in the effective transfer of heat, enhancing the performance and reliability of heat exchangers.

MC

Popularity of Our Dished End Equipment

Our dished end equipment is very popular among international clients due to its reliability and advanced features. Just last summer, we hosted a group of Russian customers who came to visit our facility. They were impressed with our technology and the quality of our equipment, leading to fruitful discussions and potential collaborations. Their visit underscored the global appeal and trust our equipment commands in the industry.

MC

A Warm Welcome to Our Esteemed Azerbaijani Customers

We extend our heartfelt greetings to our esteemed Azerbaijani customers who will soon grace us with their presence. Your journey from afar is a testament to our shared commitment to quality and innovation in the realm of industrial equipment. We eagerly anticipate showcasing our advanced dished end technology and forging lasting partnerships. Your visit is not just a meeting; it’s an opportunity to build bridges and explore mutual growth. Welcome to our facility; we look forward to a fruitful and memorable experience together.