What is the difference between a three-roll four-roller plate bending machine-Dalian Mingcheng

Release Time : 2020-10-19 View Count : 次The plate rolling machine is a kind of public forging machinery and equipment that can bend non-metallic plates into cones, spheres, cylinders or other shapes. This performance is used in a wide range of industries, boiler steam, chemical, non-metallic Construction and machine building and other businesses. Due to the different fields of use, the types of bending machines are also different. From the number of rollers, it is divided into three-roller and four-roller.

So, what are the differences between the four-roller and the three-roller? Let's take a look with Mingcheng!

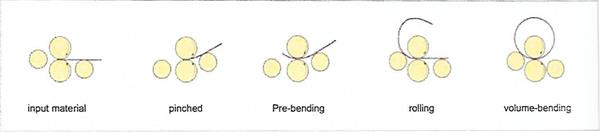

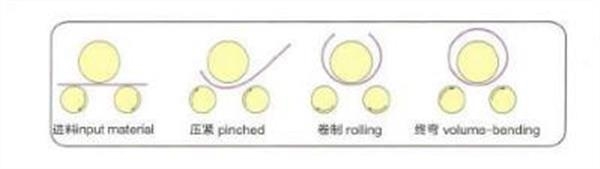

The four-roller plate rolling machine is suitable for the bending and forming of metal sheets. It can roll round, arc and tapered workpieces within a certain range. It has the function of pre-bending the end of the sheet. The remaining straight edges are small, and the work efficiency is high. The sheet metal can be roughly leveled on this machine.

The upper roller of the three-roller bending machine is at the symmetrical position of the two lower rollers through the hydraulic oil in the hydraulic cylinder acting on the piston to move vertically, and the final gear of the main reducer drives the gears of the two lower rollers to mesh for rotating movement, which is the rolling motion Provide torque.

In addition, the four-roller and three-roller have different roller motions. But their working principles are the same, they all use the principle of three-point fixed circle to roll different radii.

There are many types of plate rolling machines, and the structure and performance of each type of product are quite different. Therefore, we must have a full understanding of them when purchasing and not blindly. For many years, Chaoli manufacturers have focused on the R&D and production of various types of plate rolling machines, and they are professional because of their focus.