Tube Fiber Laser Cutting Machine

Introduction: In the world of modern manufacturing and metalworking, efficiency, precision, and flexibility are paramount. The Tube Fiber Laser Cutting Machine is at the forefront of this technological evolution. In this blog post, we'll dive into the remarkable world of Tube Fiber Laser Cutting Machines, highlighting their main functions and unique product features. Whether you're a seasoned industry professional or just exploring your options, understanding the capabilities of these machines can revolutionize your metal fabrication processes.

Unveiling the Tube Fiber Laser Cutting Machine: Main Functions

The Tube Fiber Laser Cutting Machine is a game-changer, offering a host of impressive functions that make it an invaluable tool in the world of metal fabrication. Here are its key functions:

High-Precision Cutting: The machine utilizes advanced fiber laser technology to achieve extremely precise and clean cuts on various tube materials. This precision ensures minimal material wastage and enhances the quality of the finished product.

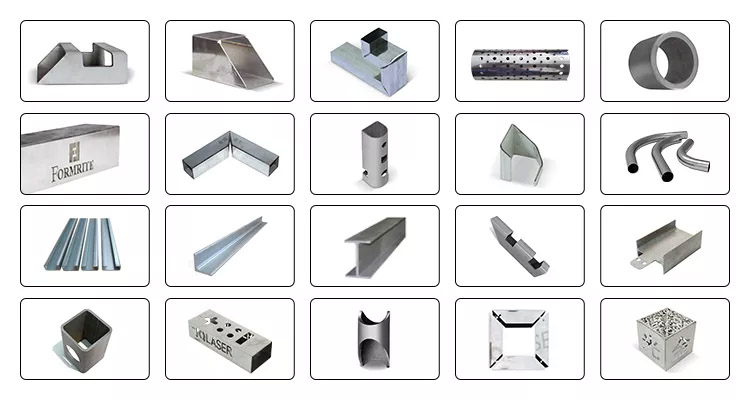

Versatility: It can cut a wide range of tube profiles and shapes, from round and square to rectangular and more. This versatility means it can adapt to the demands of diverse projects.

High-Speed Cutting: The Tube Fiber Laser Cutting Machine operates at high speeds, significantly reducing production time. This efficiency translates to increased productivity and lower manufacturing costs.

Automation: Many models come equipped with automation features, including automatic loading and unloading systems. This minimizes the need for manual labor, making production processes smoother and more efficient.

Intricate Designs: The machine can cut intricate and complex designs, making it ideal for applications such as custom metalwork, architectural elements, and more.

Smooth Edge Quality: It delivers clean and smooth cut edges, eliminating the need for additional finishing processes. This saves both time and resources.

Minimal Maintenance: With its robust design and low maintenance requirements, Tube Fiber Laser Cutting Machines offer cost-effective operation over the long term.

Product Features that Set It Apart

The Tube Fiber Laser Cutting Machine boasts a range of features that set it apart from traditional cutting methods:

Fiber Laser Technology: These machines employ advanced fiber laser sources that are highly efficient and have a longer lifespan compared to traditional lasers.

User-Friendly Interface: Many models come with user-friendly control interfaces, making them accessible to operators with varying levels of experience.

Safety Measures: Built-in safety features such as protective enclosures, sensors, and interlocks ensure the well-being of operators.

Energy Efficiency: Tube Fiber Laser Cutting Machines are designed to be energy-efficient, reducing both operational costs and environmental impact.

Remote Monitoring: Some models allow for remote monitoring and diagnostics, making maintenance and issue resolution more convenient.

Ready to Transform Your Metal Fabrication Process?

If you're ready to take your metal fabrication to the next level, the Tube Fiber Laser Cutting Machine is a technology that can't be ignored. Its precision, versatility, and efficiency make it an ideal solution for a wide range of industries, from automotive and aerospace to architecture and art.

Whether you're interested in upgrading your equipment or exploring the potential of Tube Fiber Laser Cutting for the first time, we're here to assist you. Our team of experts is ready to answer your questions and guide you in finding the perfect solution for your specific needs. Don't hesitate to reach out and start the journey toward more efficient and precise metal fabrication.

Conclusion:The Tube Fiber Laser Cutting Machine is a technological marvel that's transforming the metalworking industry. Its precision, versatility, and efficiency make it a valuable asset for manufacturers and artisans alike. If you're ready to harness the power of this innovation, we're here to help. Contact us to explore how the Tube Fiber Laser Cutting Machine can elevate your metal fabrication processes to new heights.

Are you in search of precision and efficiency for your metal fabrication projects? Look no further than the Tube Fiber Laser Cutting Machine. This cutting-edge technology offers a myriad of benefits, making it an indispensable tool for industries ranging from metal fabrication to automotive.

Understanding Laser Tube Cutting Machine

A laser tube cutting machine is an automatic CNC metal cutter designed for square, round, and special-shaped pipes made of various materials such as stainless steel, carbon steel, mild steel, galvanized steel, iron, copper, brass, and aluminum. Its applications extend from straight cutting to bevel cutting, perforation, 45-degree angle cutting, joint cutting, bevel splicing, and more.

Why Choose a Laser Tube Cutter?

Precision Beyond Comparison: Laser-cut metal boasts significantly higher precision compared to plasma cutting, flame cutting, water jet cutting, and wire cutting. The dieless cutting system ensures accuracy without the need for additional grinding.

Versatility in Applications: The machine excels in diverse industries, including metal fabrication, kitchenware, automotive, medical equipment, hardware, and fitness equipment. It replaces traditional processing methods, offering a seamless solution for cutting, chamfering, and creating complex pipe structures.

Time and Cost Efficiency: Eliminating the need for multiple processing procedures like drilling, milling, sawing, and punching, the laser tube cutter streamlines operations. It enables mass production, reduces logistics time, and minimizes material waste, ultimately saving costs and enhancing efficiency.

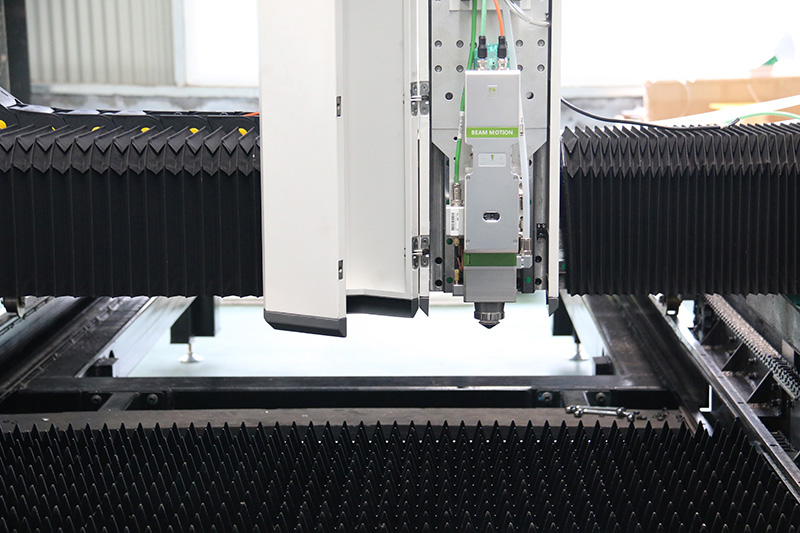

Working Principle of Laser Tube Cutter

Utilizing computer-aided design software, the laser tube cutter automates cutting by importing the operating system. The thermal energy generated by the laser beam collaborates with the motion mechanical system to achieve precise pipe cutting. The intelligent system ensures high-quality, uniform production.

Advantages of CNC Laser Tube Cutting Machine

1. Cutting Accuracy:

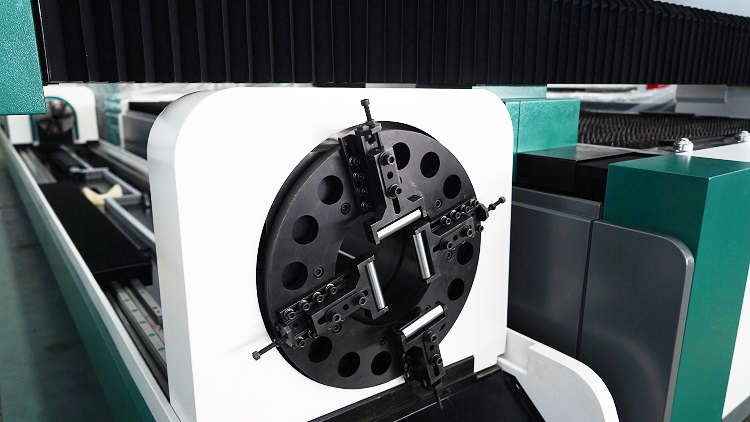

The chuck and push-type cutting methods provide high centering accuracy, ensuring precise processing. The automatic pipe cutter adjusts for deformations, guaranteeing accuracy beyond traditional processes.

2. Mass Production:

The machine allows for unified operations, reducing logistics time. With a standard pipe length of 6 meters, laser processing simplifies clamping and positioning, enabling batch processing.

3. Fiber Laser Technology:

Featuring a fiber laser with flexible transmission, the machine requires minimal maintenance. The powerful cutting function accommodates various tube shapes and materials, ensuring cost-effectiveness and low maintenance costs.

4. CNC Laser Tube Cutter Software:

Equipped with tube cutting software, the machine seamlessly recognizes pipe fitting graphics, supporting automatic generation of common pipe workpieces. The high flexibility enables quick adjustments, providing technical support for personalized processing.

Technical Parameters of Fiber Laser Tube Cutting Machine

- NO.ItemParameterUnit1Cutting Size(L*H)3000×1500mm2X-axis travel1550mm3Y-axis travel3050mm4Z-axis travel120mm5X,Y positioning accuracy±0.05/1000mmmm6X,Y repeat positioning accuracymm±0.03/1000mmmm7Acceleration1Gm/s²8Max running speed80m/min9Maximum platform load900kg10Machine size (L* W *H )4700×2200×1600mm11Laser power1kw-6kw12Control systemFSCUT2000Cw13Total power20-40kw14Machine voltage380v/50Hzkw

Features of STYLECNC Fiber Laser Tube Cutting Machine

Sturdy Construction: The machine bed undergoes 600℃ heat treatment, ensuring 20 years of usage without deformation.

High-Quality Laser Source: Utilizes China's best brand, Raycus or Germany's IPG fiber laser generator for superior cutting quality.

Optimized Cutting Head: Features a Swiss Raytools brand laser cutting head with efficient airflow design.

Rotary Device: Adopts multiple automatically segmented feeding methods for fast and precise clamping, reducing material waste.

Cypcut Software: Equipped with the Cypcut software for the numerical control system, meeting diverse tube cutting requirements.

Flexible Gas System: Allows simultaneous access to three different auxiliary gases, enhancing cutting capacity for hard materials.

Cost Considerations for Laser Tube Cutter

The cost of a laser tube cutting machine is influenced by various factors, including laser generator, cutting head, numerical control system, servo motor, rack and pinion, bed frame, beam, chiller, and air compressor. Considerations for wall thickness, laser power, tubing length, and brand differences contribute to the overall cost.

- Average Market Cost: Around $50,000

- Professional 1000W Laser Tube Cutter: Starts at $47,500

- High-End Types with Automatic Feeding System: Priced from $70,500 to $117,500

- Dual-Purpose Sheet Metal and Tube Laser Cutting Machine: Costs from $42,500 to $122,000

Shipping costs should be considered for overseas purchases, and many dealers offer free shipping promotions for local depot pickups.

Applications and Projects

The applications of the CNC laser metal tube cutting machine are vast, covering metal tubes and pipes with a diameter of ≤200mm and cutting thickness of ≤8mm (mild steel). It excels in handling round, square, triangle, rectangle, oval, circular tubes, and other special tubes. Projects include round and square tube applications, showcasing the machine's versatility.

Types of Metal Tubes Cut with a Fiber Laser Cutter

The laser tube cutter handles various metal pipes made of steel, iron, aluminum, copper, brass, and titanium. It categorizes them based on applications, manufacturing methods, materials, outer diameters, shapes, end statuses, and pressure occasions.

Metal Tube Cutting Machine Package

The machine is meticulously packaged to ensure safe delivery, including strong water-resistant plywood, separate cases for the laser source, and spare parts. Protective measures such as foam corner protection and vacuum packing guarantee the machine's integrity upon arrival.

Pre-Sale and After-Sale Service

Pre-Sale Service:

Free Sample Cutting Service: Experience the machine's capabilities with free sample cutting/testing.

Progressing Solution Design: Tailored solutions for higher manufacturing efficiency and superior processing quality.

Customized Machine Design: Modifications based on customer applications for enhanced production efficiency.

After-Sale Service:

Comprehensive Training: Provide training videos, user manuals, and remote technical support for installation, operation, and maintenance.

On-Site Training: Offer face-to-face training at the factory or the customer's location.

Warranty: A 1-year warranty for the whole machine, with long-term maintenance and certificate support (CE, FDA, SGS).

Quotation Process:

To receive a free quotation, customers are guided to answer specific questions related to their cutting needs, materials, and preferences.

Things to Consider in Operation

Circular Hole Cutting: Attention to the one-to-one cutting plan ensures satisfactory results for circular hole cutting. The size and difficulty of the hole are inversely proportional.

Gas Pressure: Proper gas pressure is crucial for smooth cutting. Too much or too little pressure can lead to rough edges or failed operations.

Machine Debugging: Before cutting operations, the machine should be thoroughly debugged using waste materials. Additionally, skilled operators and regular maintenance are essential for optimal performance.

In conclusion, the Tube Fiber Laser Cutting Machine is a game-changer in the world of metal fabrication, offering precision, efficiency, and versatility. From its working principle to technical specifications and service offerings, this comprehensive guide provides valuable insights for those seeking excellence in metal cutting technology. Embrace the future of metal fabrication with the CNC laser tube cutter. If you have any inquiries or need further assistance, feel free to contact us. Your journey to superior metal cutting starts here!