Aluminum Melting Furnace

Description

Common aluminum melting furnace types are mostly rectangular or garden-shaped two structural forms, reasonable aluminum melting furnace structure design can significantly improve the furnace heat transfer effect, improve melting capacity, and reduce energy consumption.

It can achieve the effect of reducing consumption, reducing burning, improving product quality, reducing labor intensity, improving working conditions, and improving production efficiency, suitable for intermittent operations, with more smelting of gold and return materials.

Features:

1. With renewable biomass pellet fuel as an energy source, the use cost is low.

2. Semi-gasification combined combustion with tangential swirl air distribution design, low-temperature stage combustion, and burnout rate of more than 98%.

3. Micro-positive pressure operation, no tempering, and defining phenomenon.

4. Low emission of soot, sulfur, and nitrogen.

5. Adopt air-cooled protection, simple refitting, automatic feeding, and simple operation.

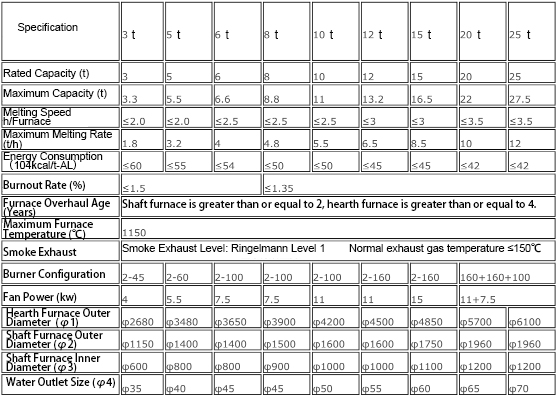

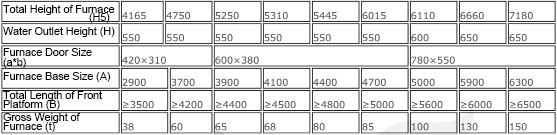

Main Technical Parameters