Coal Gas Furnace

Description

In recent years, with the development of science and technology, the energy-saving and environmental protection effect, cheapness and heating performance of the gasifier have been fully affirmed by the majority of industrial users. Especially in the building ceramics industry, the role of the gas generator is even more important.

Now the coal gasifier is developing towards miniaturization, simplification, environmental protection and low production cost, and towards on-site production and on-site use, so as to minimize the operation links and reduce energy loss.

Working Principle

The gas generator is a device that uses coal as raw material to produce gas for use in gas equipment. The solid raw coal is fed from the top of the furnace and moves downward with the operation of the gas furnace.

When it meets the gasification agent (air, steam) entering from the bottom of the furnace, it is heated by the high-temperature gas in the fuel layer at the bottom of the furnace, and physical and chemical processes occur. The reaction produces crude gas. This crude gas (hot gas) can be directly used by combustion equipment after rough dust removal. This creates several zones in the gasifier, generally referred to as "layers".

Range of Work

The gas generator is a device that provides mixed generator gas for thermal processing workshops in machinery, metallurgy, building materials, light industry, chemical industry, refractory and other industries.

The gas generator is equipped with a single-bucket lifting coal loading machine, adopts a double-sealed bell jar coal feeding box for automatic coal feeding, and uses a wet ashtray for automatic slag removal. The grate transmission mechanism is all designed outside the furnace, which is reliable in operation and easy to install and maintain.

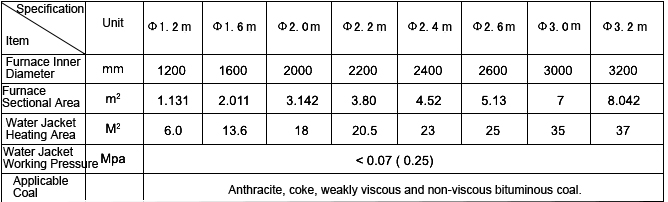

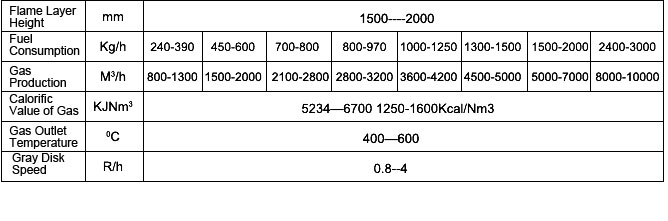

Main Technical Parameters