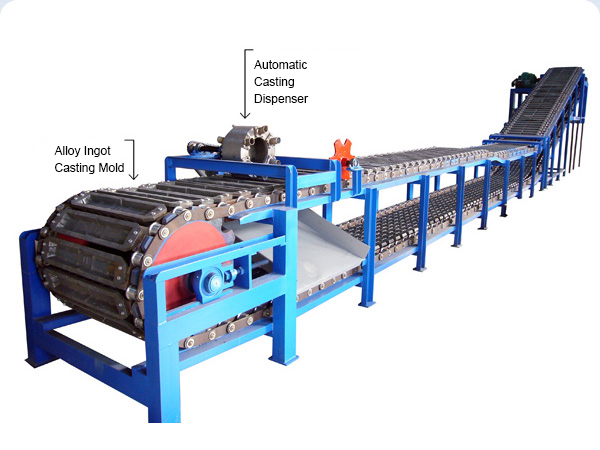

Aluminum Ingot Casting Machine

Description

This equipment is widely used by manufacturers of aluminum alloy ingots and zinc alloy ingots. It has the characteristics of automatic distribution of aluminum water, adjustable casting speed, automatic ingot molding and demolding, high production efficiency, the uniform weight of aluminum ingots, no size, smooth surface, etc.

Working Principle

The casting process of the casting machine has a high degree of automation and low labor intensity. The casting mold is made of nodular cast iron and has a long service life.

The drive motor of the machine is an AC motor, and the speed regulation method is frequency conversion step-less speed regulation.

The equipment is linear, the weight of the ingot is automatically filled with liquid, and the labor intensity is low; the automatic demolding air hammer is adopted, and the operation is more convenient; the ingot mold is made of manganese-containing cast iron, so the ingot mold has a long service life; the ingot mold is cooled by water type cooling, so as to ensure the quality of the ingot and increase the output of the casting machine by 20-30%.

Range of Work

The aluminum ingot casting machine is used for automatic control to produce cast aluminum ingots of various brands, which can meet the needs of 24-hour continuous production.

Structure

The aluminum ingot casting machine is composed of a frame, an ingot mold, a demolding mechanism, a main transmission mechanism, a water cooling device (or a water spray cooling device), and an aluminum liquid distributor.