Aluminum Profile Aging Furnace

Description

An aluminum alloy aging furnace is an energy-saving periodic operation furnace, mainly used for the aging of aluminum alloy castings, aluminum alloy dies castings, aluminum alloy wheels, aluminum profile wires, aluminum alloy plates, aluminum alloy grid plates, pistons, etc. under high uniform temperature heat treatment.

Range of Work

An aluminum alloy aging furnace is a special equipment used to eliminate the preheating of aluminum alloy materials after primary processing. It is the main equipment to reduce the stress concentration of aluminum alloy materials and reduce the deformation of aluminum alloy materials.

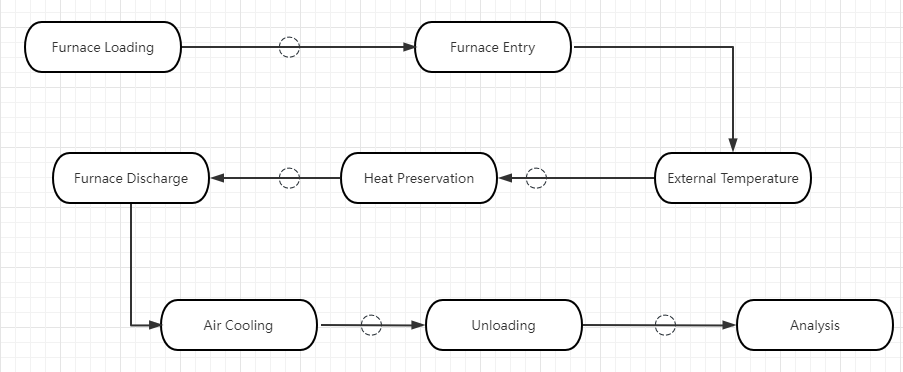

Working Process

Structure

The aluminum profile aging furnace is composed of a furnace shell, furnace lining, trolley, trolley traveling mechanism, heating element, furnace door, and other major components.

The temperature of the electric furnace is controlled through a special control cabinet and instrument indication. The furnace lining adopts a full-fiber structure, so it has the characteristics of small empty furnace loss, fast heating, low surface temperature, and a good energy-saving effect.