Water Knife Plasma Cutting Machine

Water cutting is also a cold cutting, dust-free, smokeless, non-toxic and odorless work, cutting speed, high precision, small and smooth incision.

The equipment has been widely used in metal, ceramic, stone, automobile, aviation and other fields.

FLDW1325 water cutter performance characteristics

The machine tool adopts cantilever structure. The X and Y lead rods are directly connected to the motor through the elastic coupling, absorbing vibration and providing higher transmission accuracy.

Can be loaded and unloaded in three directions. Overcome the gantry type machine tool can only feed from both ends and the blank material size is limited, cantilever machine can be placed than the size of the cutting platform blank.

In the process of operation, the two sides of the gantry machine tool screw feed is not synchronized and the fabric pressure is not uniform resulting in machine damage and can not guarantee the cutting accuracy.

High quality servo drive system is adopted, and the screw guide is adopted by international famous brand to ensure the smooth transmission of the whole machine.

Quick cut, smooth cut, no dust, no thermal deformation, no pollution, reduce material waste and other characteristics.

The bed is separated from the cutting platform. Not affected by vibration during cutting, improve the cutting accuracy.

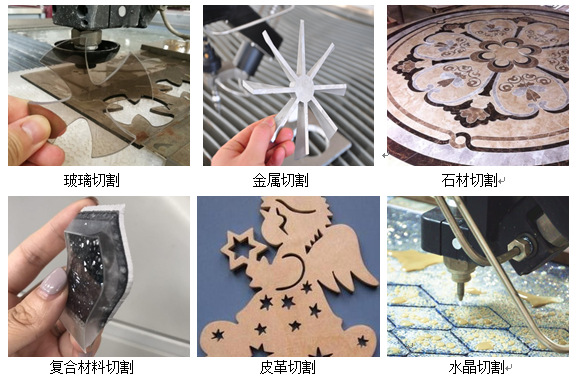

FLDW1325 water cutter application industry

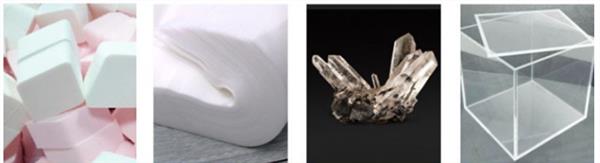

Cutting material is not restricted (stainless steel, steel, copper, aluminum and other metal, glass, stone, glass, ceramics, plastics, composite materials, especially for thickness above 80 mm hard material cutting processing (such as steel, aluminum, copper and other metal materials and stone, etc.), as well as to the cutting surface quality and cutting speed has taught high requirements of the occasion.

Basic parameter of the working form

工作台尺寸Working table size | 1.2m×1.2m 1.5m×1.5m 2.0m×1.5m 2.5m×1.5m |

切割精度/Cutting accuracy | ±0.1mm |

重复精度/Repeating accuracy | ±0.02 |

X轴运行速度/Running speed of X axis | 0—20000mm/min |

X轴电机功率/Motor power of X axis | 0.75KW |

Y轴运行速度/Running speed of Y axis | 0—20000mm/min |

Y轴电机功率/Motor power of Y axis | 0.75KW |

Z轴运行速度/Running speed of Z axis | 0—1000mm/min |

Z轴电机功率/Motor power of Z axis | 0.20KW |

Z轴行程/Z axis Stroke | 200mm |

电机/Motor | 松下交流伺服电机/Panasonic AC Servo |

运动部件Running part | 台湾“HIWIN”直线导轨/滚珠丝杆”保证设备运行速高达20000mm/min |

控制电柜 CNC controller

控制系统/Controller system | CNC 驱动器/CNC Controller |

切割软件/Cutting software | (NC Studio V-9.38).基于windows xp |

操作界面/Operation language | 中文/英文可任意切换 |

电源/Power | 三相 220V/380V/415V 50Hz |

设备外形尺寸/Machine surface diameter | 1700×1300×2000mm |

重量/Weight | 1200Kg |

机体设定区域 /Machine settings are | ≧7m2 |

额定压力/Rated voltage | 380MPa/psi |

工作压力/Working pressure | 320-360MPa/psi |

增压比/Boost ratio | 20:01 |

电压/Voltage | 220V/380V/415V 50Hz |

总功率/Total power | 30kw |

混砂管内孔尺寸/Size of nozzle | 0.76mm/1.02mm |

水喷嘴(宝石)直径/Diameter of orifice | 0.30mm |

最大用砂量/Max. sand capacity | 0-300g/min |

最大冲程数/Max. stroke | 50 times/min |

水源/Water | 大于0.4Mpa(more than 0.4 Mpa) |

The form is for reference only, please consult the staff for more information

Sample display