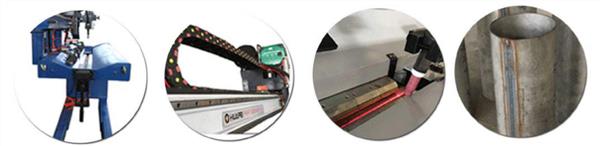

Longitudinal Seam Welding Machine

Straight seam welding is used to weld the vertical seam of the cylinder to the vertical seam of the plate. Suitable for gas shielded welding and argon arc welding autolysis (wire filling) and other welding methods.The workpiece is compressed by air bag type mechanism, and the full-length range of the workpiece is in full contact with the welded copper strip after compaction, so as to realize single-side welding and two-side molding to ensure the welding quality. It has a shielding device to protect the workpiece from deformation in the welding process, and the reverse weld is beautiful in shape.The equipment adopts PLC control to realize automatic welding operation!

Machine characteristics:

1. The machine adopts the key-type copper alloy pressing mechanism to provide uniform and stable workpiece clamping and cooling effect;

2. Equipped with welding back protection bushing and forming groove to ensure stable gas protection and perfect effect of single-side welding and double-side forming;

3. The machine can choose PLC or relay integrated control as required;

4. The welding gun is driven by DC motor, and the welding speed is stepless and adjustable;

5. Can match any type of arc welding power source (argon-arc /CO2 welding/plasma arc welding);

6. Humanized design of equipment, only ordinary workers can operate, to solve the factory recruitment difficult to recruit welding master more difficult, low production efficiency;

7. Automatic straight seam welding is mainly used for the high quality, low deformation automatic straight welding of stainless steel, iron, aluminum, brass and other metal cylinders and assembly plates.

Main Technical Parameters

型号 Model 项目 Item | TZF-300 | TZF-500 | TZF-800 | TZF-1000 | TZF-1200 | TZF-1500 | TZF-2000 |

输入电压 Input voltage | Single Phase 220V, 50/60Hz | ||||||

最大焊接长度(mm) Max welding length | 300mm | 500mm | 800mm | 1000mm | 1200mm | 1500mm | 2000mm |

工件直径 (mm) Workpiece diameter | 50-800mm | 70-800mm | 90-800mm | 100-800mm | 100-800mm | 120-800mm | 180-800mm |

适用厚度 (mm) Workpiece thickness | 0.3-3mm | 0.4-3mm | |||||

焊接速度 Welding Speed | 300-2000mm/min | ||||||

Main features of straight seam automatic welding machine

Welding main machine adopts cantilever structure, two cantilever beams after welding annealing stress treatment, to ensure that the beam long-term deformation;

Pneumatic key-type pressing structure is arranged closely along the two sides of the straight seam to ensure that the butt weld is pressed evenly throughout the welding length range;

The distance between the pressure fingers of the piano keys can be adjusted to adapt to the welding of different parts;

According to the thickness of the workpiece, air bag type or cylinder type can be used to ensure that there is enough compression force to prevent thermal deformation in the welding process;

The welding mandrel is inlaid with copper molding tool, which provides the protection function of weld seam.

According to the barrel or plate workpiece processing different welding technology groove, achieve single-side welding and double-side forming;

The distance between the welding mandrel and the keyboard is adjustable, which can meet the welding requirements of different workpieces.

The welding gun is driven by DC servo motor and driven by pinion and rack. The track surface is grinded, so the walking is stable and the welding is stable and reliable.

All air pipes and cables shall be placed in the towing chain to ensure a clean and beautiful appearance and avoid cable breakage.

Automatic straight seam welding machine.

USES:

It is used for butt joint of straight seam of various medium and thin steel, and for butt joint of cylindrical parts, suitable for various arc welding power sources.

Main configuration:

Cantilever structure, by the frame, cantilever beam, supporting shaft, keyboard board, the middle mechanism, padlock, welding gun walking mechanism, welding gun clamping and adjusting mechanism, electrical parts, etc.

Alignment mechanism has pneumatic alignment nail alignment, two forms of manual cutter plate alignment.

Welding torch moving mechanism:

Linear bearing guide, synchronous belt drive or gear bar drive, DC motor drive, motor power 65W, stepless speed regulation.

Welding gun regulating mechanism: pneumatic gun lowering mechanism, aluminum alloy cross adjusting frame, welding gun 3D, adjusting range X=50mm, Y=50mm.

One dimensional rotation adjustment.

Electric control, PLC control, electric control box in the chassis, operating box in padlock end.

Power supply: TIG/MIG.