QC12Y Hydraulic Guillotine Plate Shearing Machine

QC12Y hydraulic guillotine plate shearing machine technical description

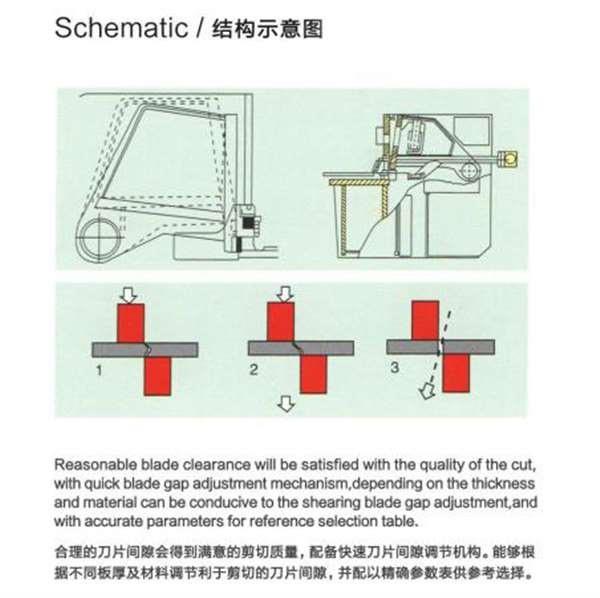

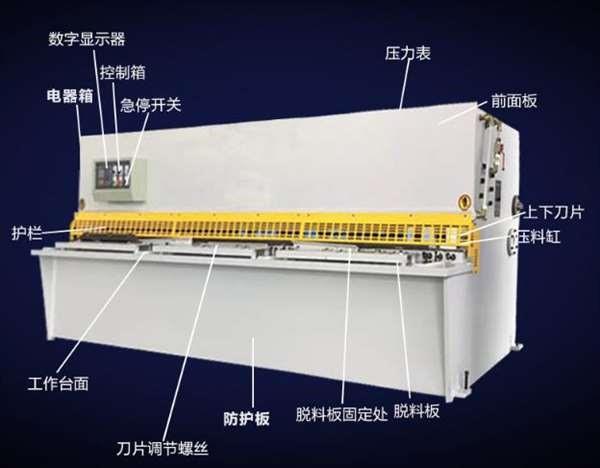

The machine uses a hydraulic transmission frame constructed of welded steel plates, which has sufficient strength and steel hardness. After maneuvering, it is equipped with a digital display structure with manual fine-tuning display, a quick adjustment mechanism for knife edge gap and optical calibration installation, which is convenient for marking and cutting. Counting fixed-length installation and flexible and reliable safe installation can be equipped with synchronous dragging and turning trolleys.

QC12Y hydraulic guillotine plate shearing machine main components and structure description

1. Frame: Frame structure welded by steel plate with good rigidity. Two cylinders are fixed on the left and right columns. There is an auxiliary tool rest on the surface of the worktable, which is convenient for fine adjustment of the lower tool rest. The outer surface of the worktable is equipped with a feeding ball for easy operation.

2. Material pressing installation: It consists of several material pressing cylinders installed on the front support plate of the frame. After the pressure cylinder is supplied with oil, the pressure head restrains the spring tension to compress the plate. After the shearing is completed, it is restored by the tension of the spring.

3. Front and rear stop: Place the front stop on the work surface, use a ruler to indicate the value, adjust the movable stop, and reach the required stop value. When cutting thin plates, the front stopper is used; the rear baffle is installed on the upper knife holder and swings up and down with the upper knife holder. The adjustment of the tailgate is driven by a motor and driven by a screw after gear reduction, which can be fine-tuned manually.

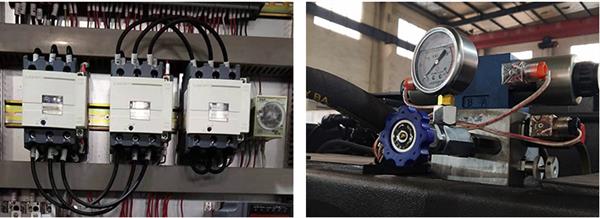

4. Hydraulic system: It is composed of control valve group, oil pump, oil cylinder, return cylinder, pressure cylinder, combined oil circuit, etc. The whole system has reasonable structure, low noise, stable operation and good safety performance.

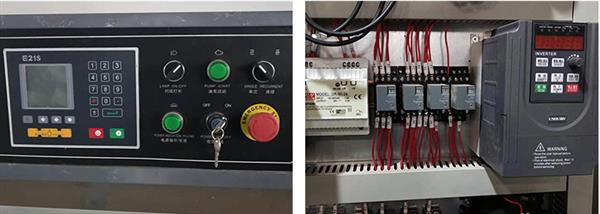

5. Electrical part: It is composed of control electrical cabinet, intermediate connection wiring, control panel, main and auxiliary motors, foot switches, etc., with high safety factor and excellent overall performance.

QC12Y hydraulic guillotine plate shearing machine details:

QC12Y series parameter form

型 号 | 可剪板厚 | 可剪板宽 | 被剪板 | 剪切角 | 后挡料距离 | 行程次数 | 喉口深度 | 电机功率 | 外形尺寸 |

(mm) | (mm) | (N/mm2) | (。) | (mm) | (次/min) | (mm) | (KW) | (mm) | |

QC12Y-6×3200 | 6 | 3200 | 450 | 0.5-1.5 | 500 | 13-22 | 130 | 7.5 | 3900×1520×2100 |

QC12Y-6×4000 | 6 | 4000 | 450 | 0.5-1.5 | 500 | 8-15 | 130 | 7.5 | 4700×1770×2200 |

QC12Y-6×6000 | 6 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 11 | 6800×1900×2550 |

QC12Y-8×2500 | 8 | 2500 | 450 | 0.5-2. | 500 | 14-24 | 130 | 7.5 | 3150×1580×2050 |

QC12Y-8×3200 | 8 | 3200 | 450 | 0.5-2. | 600 | 15-25 | 130 | 7.5 | 3740×2075×1920 |

QC12Y-8×4000 | 8 | 4000 | 450 | 0.5-2. | 500 | 8-14 | 130 | 11 | 4700×1840×2350 |

QC12Y-8×6000 | 8 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 11 | 6800×2100×2750 |

QC12Y-10×2500 | 10 | 2500 | 450 | 0.5-2 | 500 | 12-24 | 130 | 11 | 3150×1670×2150 |

QC12Y-10×3200 | 10 | 3200 | 450 | 0.5-2 | 500 | 10-18 | 130 | 11 | 3900×1730×2250 |

QC12Y-10×4000 | 10 | 4000 | 450 | 0.5-2 | 750 | 7-12 | 130 | 18.5 | 4750×1900×2450 |

QC12Y-10×6000 | 10 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 18.5 | 6950×2200×2900 |

QC12Y-10×8000 | 10 | 8000 | 450 | 0.5-2 | 900 | 4-8 | 100 | 30 | 8950×2500×3150 |

QC12Y-12×2500 | 12 | 2500 | 450 | 0.5-2.5 | 750 | 10-18 | 130 | 18.5 | 3250×1800×2280 |

QC12Y-12×3200 | 12 | 3200 | 450 | 0.5-2.5 | 750 | 9-18 | 130 | 18.5 | 3950×1870×2350 |

QC12Y-12×4000 | 12 | 4000 | 450 | 0.5-2.5 | 750 | 7-12 | 130 | 18.5 | 4800×1970×2550 |

QC12Y-12×6000 | 12 | 6000 | 450 | 0.5-2.5 | 750 | 5-10 | 100 | 30 | 7000×2250×3000 |

QC12Y-12×8000 | 12 | 8000 | 450 | 0.5-2.5 | 900 | 4-9 | 100 | 37 | 9000×2500×3300 |

QC12Y-16×2500 | 16 | 2500 | 450 | 0.5-2.5 | 750 | 9-16 | 100 | 18.5 | 3290×1890×2400 |

QC12Y-16×3200 | 16 | 3200 | 450 | 0.5-2.5 | 750 | 8-13 | 100 | 18.5 | 3970×1920×2520 |

QC12Y-16×4000 | 16 | 4000 | 450 | 0.5-2.5 | 750 | 9-12 | 100 | 30 | 9000×2500×3300 |

QC12Y-16×6000 | 16 | 6000 | 450 | 0.5-2.5 | 900 | 5-10 | 100 | 37 | 7100×2460×2920 |

QC12Y-16×8000 | 16 | 8000 | 450 | 0.5-2.5 | 900 | 4-9 | 100 | 37 | 9000×265×3400 |

QC12Y-16×9000 | 16 | 9000 | 450 | 0.5-2.5 | 900 | 3-8 | 100 | 45 | 10000×3260×3950 |

QC12Y-20×2500 | 20 | 2500 | 450 | 0.5-2.5 | 750 | 8-16 | 130 | 30 | 3350×2050×2500 |

QC12Y-20×3200 | 20 | 3200 | 450 | 0.5-2.5 | 750 | 5-14 | 130 | 30 | 4100×2080×2550 |

QC12Y-20×4000 | 20 | 4000 | 450 | 0.5-3 | 750 | 5-12 | 100 | 30 | 4900×2200×2800 |

QC12Y-20×6000 | 20 | 6000 | 450 | 0.5-3 | 900 | 4-8 | 100 | 37 | 7100×2600×3250 |

QC12Y-20×9000 | 20 | 9000 | 450 | 0.5-2.5 | 900 | 3-7 | 100 | 55 | 10050×3350×4000 |

QC12Y-25×2500 | 25 | 2500 | 450 | 0.5-3 | 900 | 6-14 | 100 | 37 | 3500×2150×2600 |

QC12Y-25×3200 | 25 | 3200 | 450 | 0.5-3 | 900 | 5-11 | 100 | 37 | 4100×2150×2650 |

QC12Y-25×4000 | 25 | 4000 | 450 | 0.5-3 | 900 | 5-10 | 100 | 37 | 4900×2280×3350 |

QC12Y-25×6000 | 25 | 6000 | 450 | 0.5-3 | 900 | 4-8 | 100 | 45 | 7100×2680×3350 |

QC12Y-30×2500 | 30 | 2500 | 450 | 0.5-3.5 | 900 | 5-11 | 100 | 45 | 3700×2570×3100 |

QC12Y-30×3200 | 30 | 3200 | 450 | 0.5-3.5 | 900 | 5-9 | 100 | 45 | 4400×2800×3250 |

QC12Y-30×4000 | 30 | 4000 | 450 | 0.5-3.5 | 900 | 4-9 | 100 | 55 | 5200×3000×3400 |

QC12Y-30×6000 | 30 | 6000 | 450 | 0.5-3.5 | 900 | 4-8 | 100 | 55 | 7100×3000×3600 |

QC12Y-40×2500 | 40 | 2500 | 450 | 0.5-4 | 900 | 4-11 | 100 | 55 | 3950×3020×3300 |

The field of plate shears

Widely used in metallurgy, light industry, machinery, hardware, electrical machinery, electrical appliances, automotive maintenance, hardware manufacturing and other metal sheet processing industries.

QC12Y hydraulic pendulum shears Operating performance characteristics:

1. The machine adopts steel plate welding structure, which has good rigidity and stability.

2. The hydraulic system is adopted to drive the pendulum motion driven by the oil cylinder, which can complete shearing and carry out the motion smoothly.

3. The machine tool is provided with a blade clearance quick conditioning mechanism and a dial indicating value.

4. After the fast operation of the block motor, manually fine-tune the counter and display the numerical value.

5. Lighting installation for simple manual marking and cutting.

6. The trip of the knife rest is adjusted by the trip switch, which effectively improves the efficiency of management and learning.

product details