Bending Machines in Modern Light Pole Production

Release Time : 2024-09-03 View Count : 次In the rapidly advancing landscape of industrial manufacturing, bending machines have emerged as essential tools in the production of light poles. As urban infrastructure continues to evolve, the demand for durable, aesthetically pleasing, and cost-effective light poles has surged. Bending machines, with their precision and efficiency, play a pivotal role in meeting these demands, ensuring that light poles not only meet stringent quality standards but also align with modern design trends. This article explores the significance of bending machines in light pole production lines, highlighting their contribution to both the manufacturing process and the final product's performance.

Bending Machines: Precision in Every Curve

Bending Machines: Precision in Every Curve

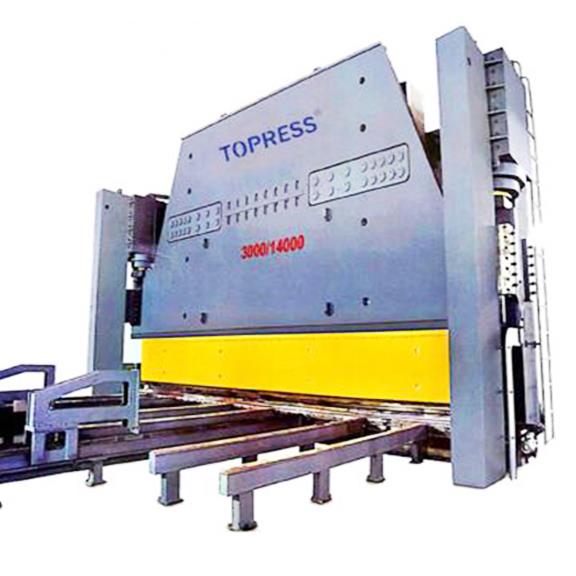

The bending process is a critical step in the production of light poles, which are typically made from materials like steel or aluminum. These materials, known for their strength and durability, require precise bending to achieve the desired shape and structural integrity. Bending machines are designed to handle these tough materials, applying consistent pressure to bend them into the required curvature without compromising their strength.

Advanced bending machines utilize computer numerical control (CNC) technology to ensure that each bend is executed with high precision. This level of control is crucial in light pole production, where even the slightest deviation from the specified dimensions can lead to structural weaknesses or alignment issues during installation.

Efficiency and Consistency in Production

Efficiency and Consistency in Production

One of the key advantages of using bending machines in light pole production is the efficiency they bring to the manufacturing process. Traditional bending methods often involved manual labor, which was not only time-consuming but also prone to errors. With modern bending machines, the process is significantly faster and more reliable.

Automated bending machines can be programmed to perform multiple bends in a single operation, reducing the need for manual intervention and minimizing the risk of errors. This not only speeds up production but also ensures consistency across large batches of light poles. Consistency is vital in maintaining the quality of the final product, as it ensures that each pole meets the required specifications and can be seamlessly integrated into the larger infrastructure.

Customization and Flexibility

Customization and Flexibility

As cities and municipalities seek to create unique and visually appealing urban environments, the demand for customized light poles has grown. Bending machines offer the flexibility needed to produce light poles with varying shapes and designs. Whether it's a simple straight pole or a more complex, architecturally inspired design, bending machines can be adjusted to create a wide range of profiles.

This customization capability allows manufacturers to cater to the specific needs of different projects, whether it's for street lighting, park illumination, or decorative lighting in public spaces. The ability to produce bespoke light poles gives manufacturers a competitive edge in the market, enabling them to meet the diverse demands of their clients.

Durability and Quality Assurance

Durability and Quality Assurance

The structural integrity of light poles is of paramount importance, as they must withstand various environmental conditions, including strong winds, heavy rainfall, and even seismic activity. Bending machines contribute to the durability of light poles by ensuring that the bends are uniform and free from defects that could compromise their strength.

Quality assurance is a critical aspect of the light pole production process, and bending machines play a crucial role in this regard. By producing consistent and accurate bends, these machines help manufacturers maintain high standards of quality, reducing the likelihood of product failures and ensuring the long-term reliability of the light poles.

Industrial Future

Industrial Future

The integration of bending machines into light pole production lines represents a significant advancement in industrial manufacturing. These machines not only enhance the efficiency and precision of the production process but also enable manufacturers to meet the growing demand for customized and durable light poles. As urban landscapes continue to evolve, the role of bending machines in shaping the future of light pole production will only become more prominent.

For manufacturers seeking to stay ahead in the competitive market, investing in state-of-the-art bending machines is not just a necessity—it's a strategic move toward ensuring the quality and longevity of their products. As cities worldwide continue to expand and modernize, the importance of reliable and well-crafted light poles will remain a cornerstone of urban infrastructure, with bending machines playing a key role in their production.

Welcome to Place Orders

Welcome to Place Orders

Our company is dedicated to providing top-tier bending machines and complete light pole production line solutions. We welcome inquiries and orders from businesses looking to enhance their manufacturing capabilities and produce light poles that meet the highest standards of quality and durability. Contact us today to learn more about our offerings and how we can support your production needs.