Efficient Punch Press for Aluminum Foil Lunch Box Production

Release Time : 2024-08-06 View Count : 次In the fast-evolving world of packaging, aluminum foil lunch boxes have emerged as a popular choice for their lightweight, durability, and eco-friendliness. These lunch boxes are increasingly favored in various industries, including food service and catering, due to their ability to keep food fresh and their convenience for on-the-go consumption. As the demand for these innovative packaging solutions continues to rise, manufacturers are seeking efficient and reliable production methods. One essential piece of equipment that plays a pivotal role in this process is the punch press.

Understanding the Role of Punch Press in Production

Understanding the Role of Punch Press in Production

A punch press is a powerful machine that utilizes a die and punch system to shape and cut materials. In the context of aluminum foil lunch box production, punch presses are primarily used to create the desired shapes and sizes from aluminum sheets. This process involves various operations, including cutting, punching, and forming, all of which are crucial to ensure precision and efficiency.

The versatility of punch presses allows them to handle different thicknesses of aluminum and produce various designs, making them ideal for manufacturers looking to diversify their product offerings. The ability to quickly switch between different die sets also means that manufacturers can efficiently respond to changing market demands.

Advantages of Using Punch Press in Production

Advantages of Using Punch Press in Production

High Precision: Punch presses are engineered to deliver accurate cuts and shapes, which is vital in producing aluminum foil lunch boxes that fit seamlessly and securely. The precision of the punch press minimizes material waste, reduces the need for rework, and ensures consistency in product quality, resulting in a more efficient production process.

Increased Production Speed: Modern punch presses are equipped with advanced technology that enables high-speed operation. This rapid processing capability allows manufacturers to significantly increase their output without compromising quality, meeting the rising demand for aluminum foil lunch boxes in a competitive marketplace.

Versatility: Punch presses can be adapted to produce various designs and sizes of lunch boxes, making them a versatile solution for manufacturers. Whether producing standard-sized boxes or custom designs, punch presses can be easily adjusted to accommodate different specifications, allowing manufacturers to cater to diverse customer needs.

Cost-Effectiveness: By streamlining the production process and minimizing material waste, punch presses contribute to substantial cost savings for manufacturers. The initial investment in punch press technology can be quickly recouped through increased efficiency, reduced operational costs, and the ability to produce higher-quality products that command better prices in the market.

The Production Process: From Sheet to Finished Product

The Production Process: From Sheet to Finished Product

The process of producing aluminum foil lunch boxes using punch presses typically involves several key stages:

Material Preparation: Aluminum sheets are prepared and cut to the required size for production. This stage ensures that the sheets are ready for the punching and forming processes, reducing lead times and enhancing overall efficiency.

Punching and Cutting: The punch press is utilized to punch holes and cut the aluminum sheets into the desired shapes. This process includes creating the base, sides, and lids of the lunch boxes, ensuring that all components fit together perfectly.

Forming: After the sheets are cut, they are fed into the forming section of the punch press. Here, the aluminum is shaped into the final form of the lunch box, ensuring that all edges are folded and aligned correctly to provide structural integrity.

Quality Control: Throughout the production process, rigorous quality control measures are implemented to ensure that each lunch box meets industry standards. This includes checking for proper dimensions, strength, and finish, ensuring that only the highest quality products reach customers.

Packaging: Once the lunch boxes are formed, they are packaged for distribution. Efficient packaging solutions are employed to ensure that the products reach customers in pristine condition, ready for immediate use.

Recent Customer Visit

Recent Customer Visit

We recently had the pleasure of welcoming customers from Turkmenistan who visited our facility to explore our aluminum foil lunch box production line machine. During their visit, they were particularly impressed with the efficiency and precision of our punch press technology. This firsthand experience allowed them to see the potential benefits of our machinery in enhancing their production capabilities.

The customers engaged in detailed discussions with our engineering team, gaining insights into how our punch presses could be integrated into their existing operations. We are excited about the possibility of partnering with them to meet their packaging needs and provide them with the tools necessary to succeed in their market.

Industry Trends and Future Outlook

Industry Trends and Future Outlook

As the demand for eco-friendly packaging solutions continues to rise, aluminum foil lunch boxes are expected to gain even more popularity in various sectors. This trend is driven by an increasing awareness of sustainability and the need for efficient packaging that minimizes environmental impact. The punch press industry is also evolving, with advancements in automation and smart manufacturing techniques that further enhance efficiency and capabilities.

Manufacturers who invest in the latest punch press technology will be better positioned to adapt to changing market dynamics and consumer preferences. The future of aluminum foil lunch box production looks promising, with opportunities for growth and innovation on the horizon.

Our Service Commitment

Our Service Commitment

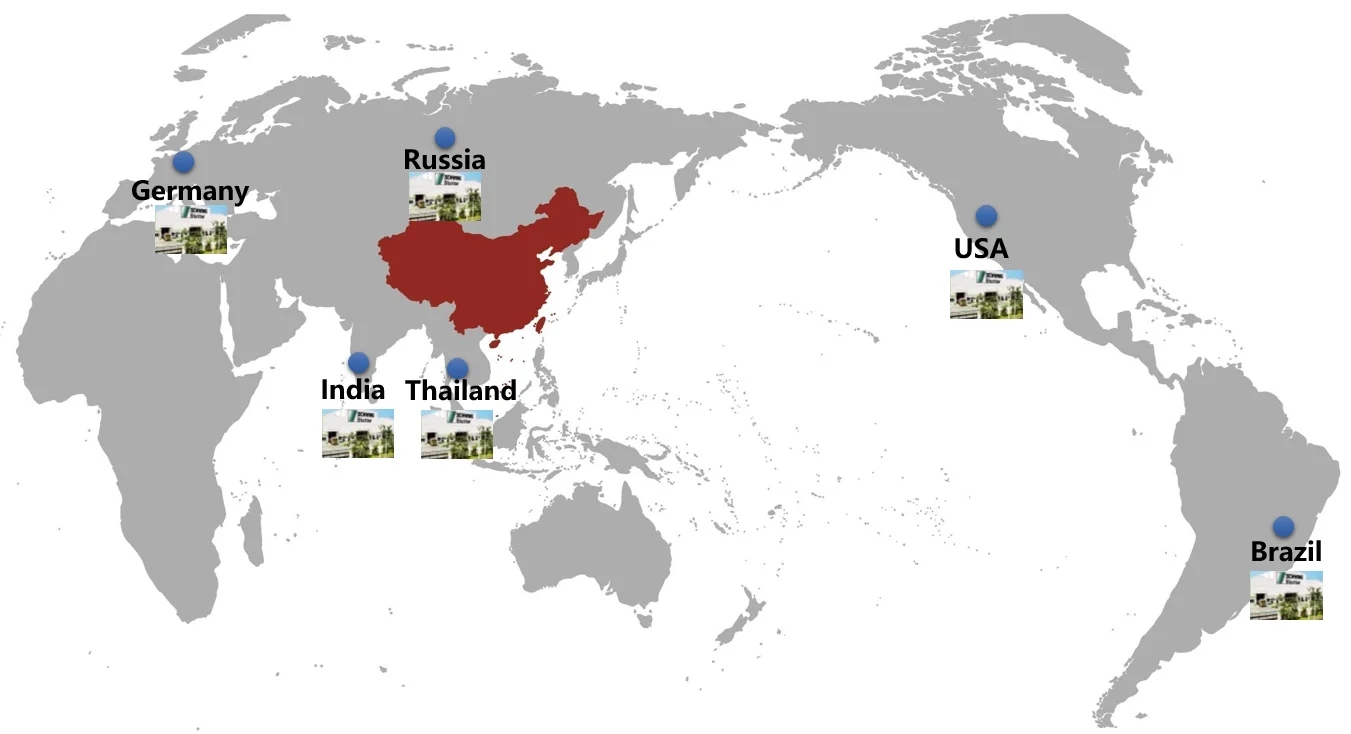

At our company, we pride ourselves on delivering not only high-quality machinery but also exceptional service and support. Our dedicated team is committed to understanding your specific production needs and providing tailored solutions that enhance your operational efficiency.

We offer comprehensive services, including consultation, installation and training, and ongoing support. Our experts will work closely with you to identify the best punch press solutions for your aluminum foil lunch box production. We provide professional installation of our equipment and thorough training for your team to ensure smooth operation and optimal performance.

Our commitment doesn’t end after installation. We offer ongoing technical support and maintenance services to keep your production running smoothly and efficiently.

Welcome to Order from Us!

Welcome to Order from Us!

The punch press is an essential component in the production of aluminum foil lunch boxes, offering numerous advantages that contribute to efficient manufacturing processes. We warmly welcome you to explore our range of punch press solutions and other machinery designed to enhance your production capabilities.

Don’t hesitate to place your orders with us; we are committed to providing high-quality equipment that meets your manufacturing needs and supports your business growth. Join us in revolutionizing your production line today!