The portable CNC cutting machine is on sale at a special price, one less than 1735!

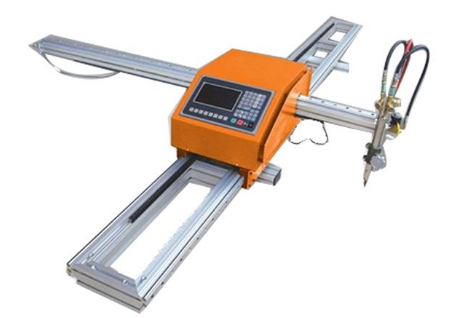

Release Time : 2020-11-06 View Count : 次The portable CNC cutting machine has a compact and micro structure. The horizontal and vertical rails of the whole machine are made of hard aluminum alloy, which reduces the weight of the equipment, so as to achieve the characteristics of easy movement, compact and flexible operation. It is an ideal upgrade product to replace handheld flame cutting equipment, handheld plasma cutting devices, profiling cutting machines and semi-automatic cutting carts. The use is as flexible and convenient as the cutting trolley, and it can be moved at will without occupying a fixed site. It is a numerical control equipment specially used for sheet metal blanking.

The portable CNC cutting machine is suitable for internal and external cutting, and can cut various metal materials according to any graphics. The roughness of the cut can reach 25 (▽3), and the cut surface after cutting generally does not require surface processing. It has the advantages of high degree of automation, convenient use, high precision, high reliability, low price, and very simple operation and maintenance.

Portable CNC cutting machines are widely used in machine tool manufacturing, petrochemical equipment, light industrial machinery, shipbuilding, pressure vessels, engineering machinery, mining machinery, electric power, bridge construction, aerospace, steel structures, boilers, radiators, and other industries.

As a necessary machine for cutting and blanking, portable CNC cutting machine are rapidly becoming popular in the world, and most companies have begun to use CNC cutting machines for production. It can be said that the use of CNC cutting machine not only greatly improves the production efficiency of the enterprise, but also saves a lot of manpower and material resources. Undoubtedly, for most SMEs, the use of portable CNC cutting machine is undoubtedly the icing on the cake. When we use the portable CNC cutting machine to create value, we can't ignore its maintenance. If the device is not protected for a long time, a series of problems will easily occur over time:

1. The environmental humidity of the portable CNC cutting machine is not balanced. Industrial computers consist of integrated circuits with many electronic components, and their insulation is very sensitive to environmental humidity. Too much humidity can easily short-circuit the circuit board and burn. Too little humidity can easily generate static electricity, which can also damage some electronic components. Therefore, it is necessary to strengthen the monitoring of environmental humidity in daily production.

2. The working surface of the portable CNC cutting machine vibrates greatly. During the production and operation of the equipment, strong noise is generated due to physical displacement actions such as tension and vibration. The vibration caused by the equipment during operation can severely damage the disks, optical drives and floppy disk drives of industrial computers. If there is a problem with the industrial computer's disk, optical disk drive and floppy disk drive, it will affect the system and cause the equipment to fail to operate normally.

3. Too much dust in the air. Because the portable CNC cutting machine generates a large amount of metal dust during the cutting process, it will penetrate into all parts of the equipment, and the long-term large-scale cutting of the CNC cutting machine will also cause the accumulation of metal dust. The equipment operation is burdensome. Therefore, it is necessary to ensure the cleanliness of the production workshop environment and timely clean up the metal dust.

4. The guide rail of the portable CNC cutting machine should be wiped and maintained frequently to ensure the normal operation of the machine. If a paper jam occurs, the voltage of the power supply motor will fluctuate greatly, and it is easy to cut off the power supply.

5. The working time of the industrial computer of the portable CNC cutting machine is too long. Perhaps due to production needs, some users' industrial control systems need to work for a long time, which brings a huge burden to the industrial computer operating system, and the internal temperature of the industrial computer is too high. In a long-term high temperature environment, the computer components are in a high temperature state for a long time. If it is not cooled down in time, it is prone to aging and hard disk failure.

The above problems are often encountered when the portable CNC cutting machine is not maintained. Therefore, we hope that our customers should pay attention to diligent maintenance during operation and use. Many customers may not know how to maintain a portable CNC cutting machine. The following are the daily maintenance issues of the CNC cutting machine. Dalian Mingcheng Machinery Equipment Co., Ltd. will explain to customers in detail:

1. After get off work, the equipment should return to a safe position and close the air valve. The residual gas in the pipeline should be discharged and the power supply should be turned off.

2. If a shift system is implemented, the operating status of the equipment on duty should be recorded.

3. The site should be carefully cleaned up to keep the work area clean and orderly.

4. The track does not allow people to stand, step on, lean on heavy objects, let alone hit them. Every time you change gears, clean the track surface with compressed air, and then wipe with gauze and oil. Always keep the slide rail surface lubricated and clean.

5. Clean the gearbox rack with engine oil every day, and there are particles splashing on the rack.

6. Only the operator is allowed to disassemble the cutting nozzle, while the rest cannot be disassembled at will. During inspection and maintenance, only relevant personnel can open the electrical junction box.

7. If the equipment fails, it should be handled by maintenance personnel in time. If the failure is large, it should be reported to the equipment department, and the relevant personnel will organize an inspection to determine the maintenance plan. It is strictly prohibited to disassemble and inspect without permission.

In daily use, the daily maintenance of CNC cutting machine is indispensable, and these small details cannot be ignored for production requirements.

Dalian Mingcheng Electromechanical Equipment Co., Ltd. was established in 2012. It is an enterprise specializing in the development and sales of CNC machine tools and automatic welding equipment. Our main products are plate shears, bending machines, plate bending machines, combined punching and shearing machines, presses, hydraulic presses, laser cutting machines, capping machines, welding equipment, polishing equipment and so on. Precautions for gauge accuracy after adjustment of QC12Y hydraulic pendulum shears.mob/whatsapp: 0086-13322202758

At present, the portable plasma cutting machine is active, with affordable price, fast delivery speed, high cost performance, and a variety of colors and styles to choose from. If you are interested, please consult us directly.