QC11Y/A Hydraulic Guillotine Shearing Machine

QC11Y series of hydraulic brake type plate shears

Product Application

Plate shears is a machine in which one blade is used for reciprocating linear motion of shear plate with respect to another blade.

It is by the movement of the upper blade and the fixed lower blade, using a reasonable blade clearance, the various thickness of the metal plate shear force, so that the plate according to the size of fracture separation required.

Shearing machine belongs to a kind of forging and pressing machinery, the main role is the metal processing industry.

The products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipping, automobile, electric power, electrical appliances, decoration and other industries to provide the required special machinery and complete sets of equipment.

working principle

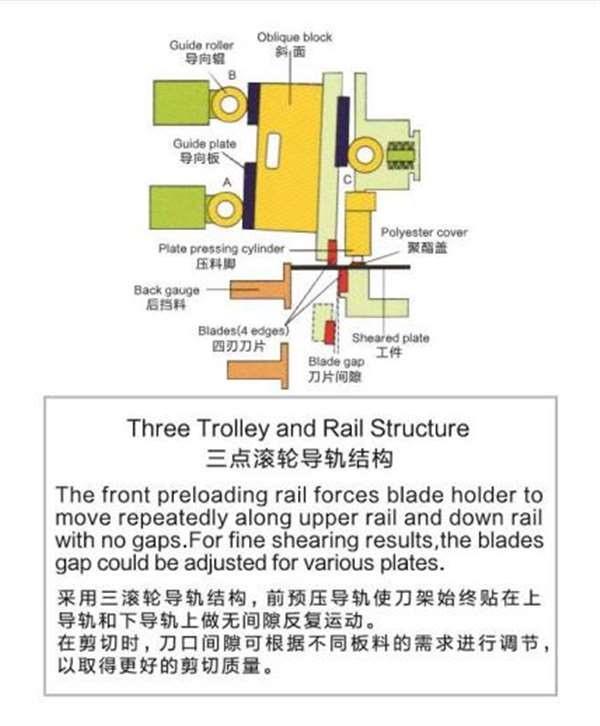

The shearing machine should be able to ensure the straightness and parallelism of the shearing surface of the sheared material after cutting, and minimize the distortion of the sheared material, so as to obtain high quality workpieces.

The upper blade of the plate cutting machine is fixed on the tool holder and the lower blade is fixed on the working table.

The working table is equipped with a feeding ball so that the sheet material will not be scratched when sliding on it.

The rear baffle is used for plate positioning and the position is adjusted by the motor.

The pressure cylinder is used to compress the sheet material to prevent it from moving during shearing.

Guardrails are safety devices to prevent work-related accidents.

The return trip usually relies on nitrogen, which has high speed and small impact.

QC11Y/QC11A Series hydraulic brake type plate shears Standard configuration:

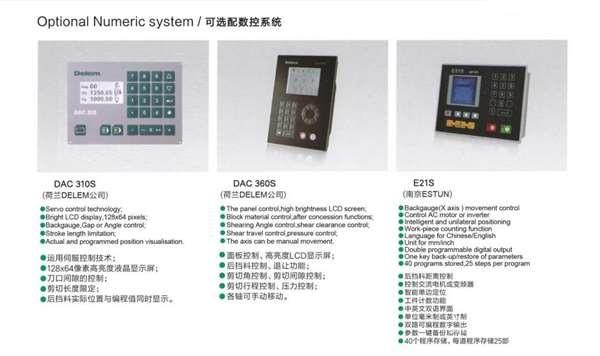

Numerical control system E21S

Rear stopper: ball screw

Blade material: 6CrW2Si (main Shear Q235)

QC11Y/QC11A series of hydraulic brake type plate shears:

Netherlands Delem: DAC 310S

Netherlands Delem: DAC 360S

Nanjing ES21S: E21S

QC11Y/A series parameter form

型 号 | 可剪板厚 | 可剪板宽 | 被剪板料强度 | 剪切角 | 后挡料距离 | 行程次数 | 喉口深度 | 电机功率 | 外形尺寸 |

Type | Cuting thickness | cutting length | Strength of sheared sheet | shear angle | Thorat Depth | Times of stroke | Throat Depth | motor power | Dimensions |

(mm) | (mm) | (N/mm2) | (。) | (mm) | (次/min) | (mm) | (KW) | (mm) | |

QC11Y/A-6×3200 | 6 | 3200 | 450 | 0.5-1.5 | 500 | 13-22 | 130 | 7.5 | 3900×1520×2100 |

QC11Y/A-6×4000 | 6 | 4000 | 450 | 0.5-1.5 | 500 | 8-15 | 130 | 7.5 | 4700×1770×2200 |

QC11Y/A-6×6000 | 6 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 11 | 6800×1900×2550 |

QC11Y/A-8×2500 | 8 | 2500 | 450 | 0.5-2. | 500 | 14-24 | 130 | 7.5 | 3150×1580×2050 |

QC11Y/A-8×3200 | 8 | 3200 | 450 | 0.5-2. | 600 | 15-25 | 130 | 7.5 | 3740×2075×1920 |

QC11Y/A-8×4000 | 8 | 4000 | 450 | 0.5-2. | 500 | 8-14 | 130 | 11 | 4700×1840×2350 |

QC11Y/A-8×6000 | 8 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 11 | 6800×2100×2750 |

QC11Y/A-10×2500 | 10 | 2500 | 450 | 0.5-2 | 500 | 12-24 | 130 | 11 | 3150×1670×2150 |

QC11Y/A-10×3200 | 10 | 3200 | 450 | 0.5-2 | 500 | 10-18 | 130 | 11 | 3900×1730×2250 |

QC11Y/A-10×4000 | 10 | 4000 | 450 | 0.5-2 | 750 | 7-12 | 130 | 18.5 | 4750×1900×2450 |

QC11Y/A-10×6000 | 10 | 6000 | 450 | 0.5-2 | 750 | 5-10 | 100 | 18.5 | 6950×2200×2900 |

QC11Y/A-10×8000 | 10 | 8000 | 450 | 0.5-2 | 900 | 4-8 | 100 | 30 | 8950×2500×3150 |

QC11Y/A-12×2500 | 12 | 2500 | 450 | 0.5-2.5 | 750 | 10-18 | 130 | 18.5 | 3250×1800×2280 |

QC11Y/A-12×3200 | 12 | 3200 | 450 | 0.5-2.5 | 750 | 9-18 | 130 | 18.5 | 3950×1870×2350 |

QC11Y/A-12×4000 | 12 | 4000 | 450 | 0.5-2.5 | 750 | 7-12 | 130 | 18.5 | 4800×1970×2550 |

QC11Y/A-12×6000 | 12 | 6000 | 450 | 0.5-2.5 | 750 | 5-10 | 100 | 30 | 7000×2250×3000 |

QC11Y/A-12×8000 | 12 | 8000 | 450 | 0.5-2.5 | 900 | 4-9 | 100 | 37 | 9000×2500×3300 |

QC11Y/A-16×2500 | 16 | 2500 | 450 | 0.5-2.5 | 750 | 9-16 | 100 | 18.5 | 3290×1890×2400 |

QC11Y/A-16×3200 | 16 | 3200 | 450 | 0.5-2.5 | 750 | 8-13 | 100 | 18.5 | 3970×1920×2520 |

QC11Y/A-16×4000 | 16 | 4000 | 450 | 0.5-2.5 | 750 | 9-12 | 100 | 30 | 9000×2500×3300 |

QC11Y/A-16×6000 | 16 | 6000 | 450 | 0.5-2.5 | 900 | 5-10 | 100 | 37 | 7100×2460×2920 |

QC11Y/A-16×8000 | 16 | 8000 | 450 | 0.5-2.5 | 900 | 4-9 | 100 | 37 | 9000×265×3400 |

QC11Y/A-16×9000 | 16 | 9000 | 450 | 0.5-2.5 | 900 | 3-8 | 100 | 45 | 10000×3260×3950 |

QC11Y/A-20×2500 | 20 | 2500 | 450 | 0.5-2.5 | 750 | 8-16 | 130 | 30 | 3350×2050×2500 |

QC11Y/A-20×3200 | 20 | 3200 | 450 | 0.5-2.5 | 750 | 5-14 | 130 | 30 | 4100×2080×2550 |

QC11Y/A-20×4000 | 20 | 4000 | 450 | 0.5-3 | 750 | 5-12 | 100 | 30 | 4900×2200×2800 |

QC11Y/A-20×6000 | 20 | 6000 | 450 | 0.5-3 | 900 | 4-8 | 100 | 37 | 7100×2600×3250 |

QC11Y/A-20×9000 | 20 | 9000 | 450 | 0.5-2.5 | 900 | 3-7 | 100 | 55 | 10050×3350×4000 |

QC11Y/A-25×2500 | 25 | 2500 | 450 | 0.5-3 | 900 | 6-14 | 100 | 37 | 3500×2150×2600 |

QC11Y/A-25×3200 | 25 | 3200 | 450 | 0.5-3 | 900 | 5-11 | 100 | 37 | 4100×2150×2650 |

QC11Y/A-25×4000 | 25 | 4000 | 450 | 0.5-3 | 900 | 5-10 | 100 | 37 | 4900×2280×3350 |

QC11Y/A-25×6000 | 25 | 6000 | 450 | 0.5-3 | 900 | 4-8 | 100 | 45 | 7100×2680×3350 |

QC11Y/A-30×2500 | 30 | 2500 | 450 | 0.5-3.5 | 900 | 5-11 | 100 | 45 | 3700×2570×3100 |

QC11Y/A-30×3200 | 30 | 3200 | 450 | 0.5-3.5 | 900 | 5-9 | 100 | 45 | 4400×2800×3250 |

QC11Y/A-30×4000 | 30 | 4000 | 450 | 0.5-3.5 | 900 | 4-9 | 100 | 55 | 5200×3000×3400 |

QC11Y/A-30×6000 | 30 | 6000 | 450 | 0.5-3.5 | 900 | 4-8 | 100 | 55 | 7100×3000×3600 |

QC11Y/A-40×2500 | 40 | 2500 | 450 | 0.5-4 | 900 | 4-11 | 100 | 55 | 3950×3020×3300 |

Main Features

1. Totally European design, streamlined looking. Monoblock steel welding frame and stress relief process by Annealing treatment.

2. Triple support rolling guide to eliminate gaps of support and enhance shearing quality.

3. As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

4. The parallelism of the sheet to be cut off and the precision of the shear size can be ensured. The cut stroke and cut times also can be controlled.

5. System uses a bladder-type hydraulic accumulator as an auxiliary energy, absorb the pressure shock, the machine is running smoothly with low noise

6. Shearing angle is adjustable, which can reduce the shearing deformation of sheet metal and can shear much thicker sheet metal.

7. European key electrics with good reliability and long working life.

8. Sliding balls/rolls inserted into work table allowing material to be easily moved to the cut position and squaring arm.

9. All seals in cylinder is imported, the most famous brand, good quality and high performance

10. Overload overflow protection is outfitted to hydraulic system, which can assure no leakage

11. The distance of the backgauge is adjusted by the motor.

12. Digital display device for distance of back gauge and shearing times available.

13. The portable and prompt motorized blade gap adjustment.

14. Adopt integrated hydraulic system, more reliable and easy for maintenance. The hydraulic system consists of motor, oil pump and valve groups and it is installed at the top of the oil box.

15. Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder.

16. Humanistic concern security design in all details and also the scientific details through KINGWELL standard.